Whatsapp lD: +86 139 1082 2188

Email : postmaster@jufeng.world

or manufacturing businesses, energy costs are often one of the largest operational expenses—and one of the hardest to control. When a leading auto parts manufacturer in Tianjin (hereafter referred to as “Tianjin Auto Parts”) approached Beijing Century Jufeng Energy & Power Technology Co., Ltd., they were facing a critical challenge: their monthly electricity bills had risen by 35% in six months, and their aging power equipment was prone to breakdowns, disrupting production.

What followed was a partnership that not only solved their immediate problems but also set them up for long-term energy efficiency. Here’s how we did it.

The Challenge: Outdated Equipment + Rising Energy Costs

Tianjin Auto Parts operates a 20,000-square-meter factory with 12 production lines, using heavy machinery (e.g., stamping presses, welding robots) that requires stable, high-capacity power. Their existing power system had two major issues:

- Inefficient Transformers: The factory’s 10-year-old transformers were losing 18% of energy as heat—well above the industry’s 8% average. This meant they were paying for electricity they weren’t even using.

- Unreliable Power Distribution: Frequent voltage fluctuations caused machinery to shut down unexpectedly. In the six months before contacting us, they had 11 unplanned downtime incidents, costing an estimated 500,000 RMB in lost production.

The plant’s manager, Mr. Li, summed up their frustration: “We were throwing money away on energy waste, and the constant breakdowns were hurting our ability to meet client deadlines. We needed a solution that was both cost-effective and reliable.”

Our Solution: A Customized Power Upgrade Plan

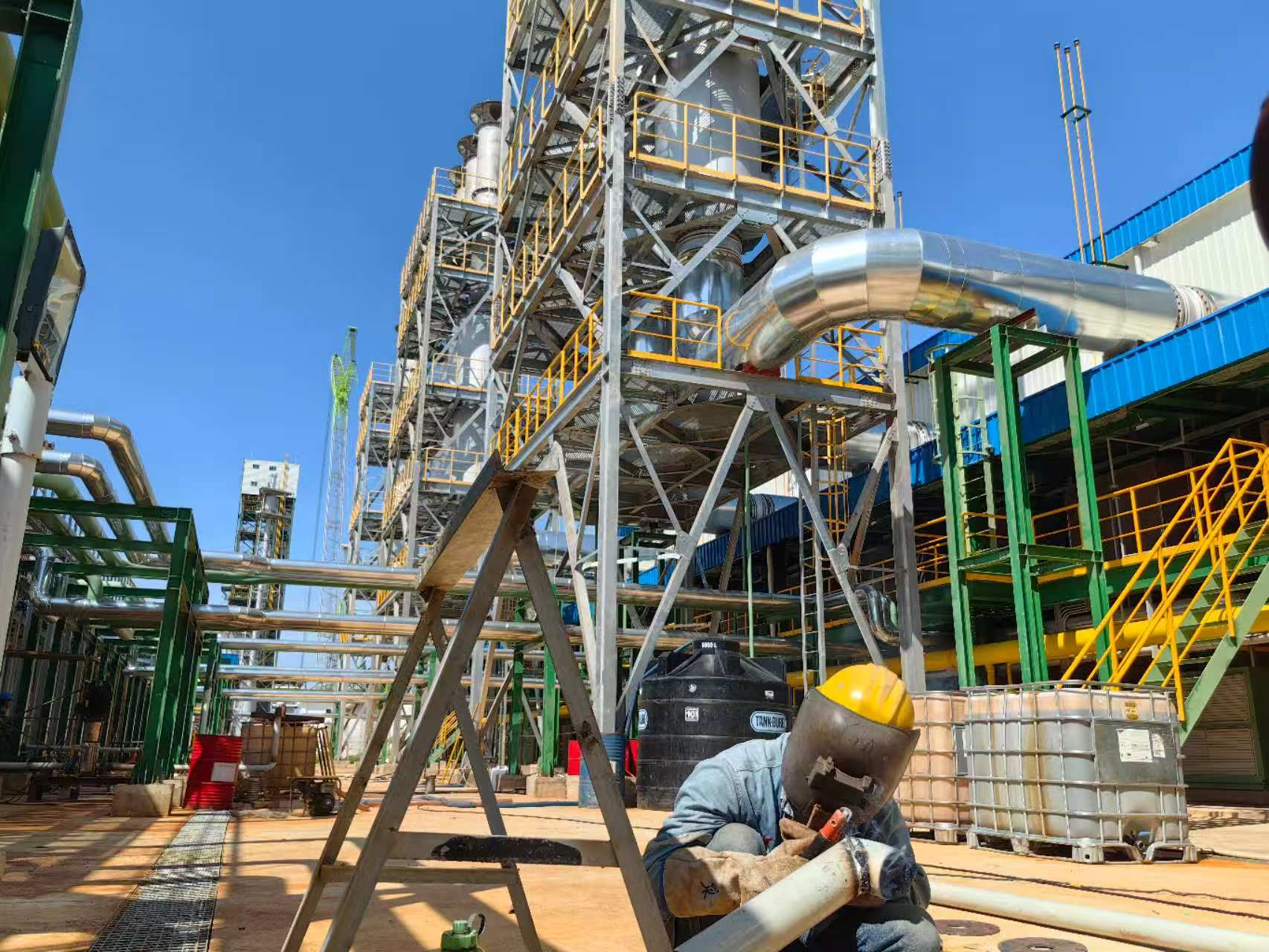

After conducting a 3-day on-site energy audit, our team identified the root causes and designed a tailored solution focused on three key areas:

1. Upgrading to High-Efficiency Transformers

We replaced the factory’s old transformers with our CJF-E Series High-Efficiency Transformers, which use amorphous alloy cores (a material that reduces magnetic loss) and optimized winding. These transformers have an energy loss rate of just 6%—a 12-percentage-point improvement over the old models. We also sized the transformers to match the plant’s actual load (the old ones were oversized, leading to unnecessary waste).

2. Installing a Smart Power Distribution System

To address voltage fluctuations, we installed our Smart Grid Monitoring System, which includes real-time voltage sensors and automatic voltage regulators. The system alerts operators to potential issues via a mobile app and adjusts voltage levels instantly—preventing breakdowns. It also provides detailed energy usage reports, helping the plant identify which machines are using the most power.

3. On-Site Training & Maintenance Support

We trained 15 of the plant’s operators on how to use the new system, including how to interpret energy reports and perform basic maintenance. We also signed a 2-year after-sales contract, guaranteeing 24/7 technical support and annual equipment inspections.

The Results: 22% Lower Costs + Zero Downtime

Six months after the upgrade, the results spoke for themselves:

- Energy Cost Savings: The plant’s monthly electricity bills dropped from 480,000 RMB to 374,400 RMB—a 22% reduction. At this rate, they will recoup the cost of the upgrade in just 14 months.

- Zero Unplanned Downtime: The smart monitoring system has prevented all voltage-related breakdowns. Mr. Li noted, “We haven’t had a single production stop since the upgrade—our clients are happier, and our team is more productive.”

- Improved Sustainability: The new transformers have reduced the plant’s carbon emissions by 180 tons per year, helping them meet local environmental regulations.

Why This Works for Other Manufacturers

This case study isn’t unique—many manufacturing plants in China face similar challenges with outdated power equipment. The key to our success with Tianjin Auto Parts was data-driven customization: we didn’t just sell them new equipment; we analyzed their specific needs, designed a solution that addressed their pain points, and provided ongoing support to ensure long-term results.

For manufacturers looking to cut energy costs, improve reliability, or reduce their carbon footprint, Century Jufeng’s approach offers a proven path forward. Every business is different, but our goal is always the same: to turn your power challenges into competitive advantages.